What are the forging methods of titanium alloys? What are the characteristics of each?

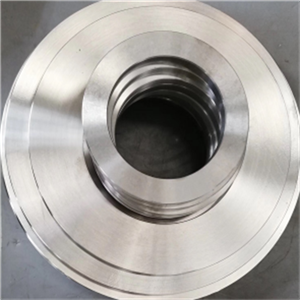

With our own factory and high quality equipment from manufacturers. We pursue higher customer satisfaction and sustainable business development, and we supply a wide variety of products, including Titanium Bar, Titanium Plate, Titanium Tube, Titanium Wire, Titanium Forging, Titanium Equipment, etc. The following will introduce to you the forging methods of titanium alloys:

(1) Free forging. Free forging is generally carried out between two flat dies or dies without a die cavity. The tools used in free forging are simple in shape, high in flexibility, short in manufacturing cycle and low in cost. However, the labor intensity is high, the operation is difficult, the productivity is low, the quality of the forgings is not high, and the machining allowance is large. Therefore, it is only suitable for use in cases where there are no special requirements for the performance of the parts and the number of parts is small. For large forgings, free forging is mainly used as a billet making process. In the free forging process, the blank can be forged into a stepped bar, or the blank can be made into simple shapes such as round cake and rectangle by upsetting or flattening.

(2) Open die forging (with burr die forging). The blank is deformed between two modules with a cavity engraved, the general part is confined inside the cavity, and the excess metal flows out from the narrow relay between the two dies, forming a burr around the forging. Under the resistance of the mold and the surrounding burrs, the metal is forced into the shape of the mold cavity

(3) Closed die forging (no burr die forging). During closed die forging, there is no transverse burr formed perpendicular to the direction of die movement. The cavity of a closed forging die has two functions; one part of it is used to form the blank and the other part is used to guide it.

(4) Extrusion die forging. Using extrusion die forging, there are two kinds of forward extrusion die forging and reverse extrusion die forging. Extrusion die forging can make a variety of titanium rings. Forgings with high geometric accuracy and denser internal structure can be obtained.

(5) Perforating punches make the metal flow outward from the center of the cavity to achieve the purpose of filling the cavity. There is no burr of ordinary forgings on the parting line of cylindrical parts.

(6) Die forging by division. In order to forge large integral die forgings on the existing hydraulic press, segment die forging methods such as segment die forging and pad die forging can be used. The feature of the subdivision forging method is to process the titanium cake piece by piece, one part at a time, so the tonnage of the required equipment can be very small. In general, this method can produce very large forgings on medium-sized hydraulic presses.

(7) Isothermal die forging. Before forging, the die is heated to the forging temperature of the blank, and the temperature of the die and the blank are kept the same throughout the die forging process, so that a large amount of deformation can be obtained under the action of a small deformation force. Isothermal die forging and isothermal superplastic die forging are very similar, the difference is that before die forging, the blank must be superplasticized to make it have fine equiaxed grains.